Why Should I Use CNC Machining? Unleash Precision and Efficiency

How Do Cryptocurrencies Affect the Sports Betting Industry

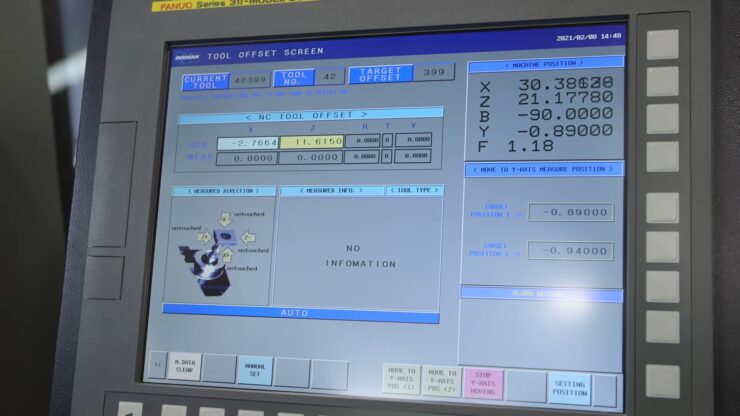

Computer Numerical Control (CNC) machining is a manufacturing process that uses pre-programmed computer software to dictate the movement of factory tools and machinery. From drilling and boring to grinding and milling, this technological marvel can perform a wide array of tasks, shaping materials into a myriad of intricate designs.

Its popularity has seen a steady rise in various industries like aerospace, automotive, and healthcare to name a few. Being an automated process, CNC machining not only speeds up production but also ensures precision and accuracy, eliminating any room for human error. Furthermore, CNC machining, and CNC machine providers such as Dassault CNC, aren’t limited to just one or two sectors.

1. Precision and Accuracy

In the world of manufacturing, precision, and accuracy are of paramount importance. When creating complex parts or components, even a hair’s breadth deviation can lead to catastrophic results. This is where CNC machining shines. It delivers exceptional precision, often reaching an accuracy within 0.001 inches.

Moreover, these machines can effortlessly maintain this precision over prolonged periods and across numerous identical parts, bringing a remarkable level of consistency to the manufacturing process. This capability is vital in industries where high precision and quality are non-negotiable, such as the medical and aerospace sectors.

2. Versatility

CNC machining displays an impressive degree of versatility when it comes to handling different materials. Metals, plastics, wood, glass, foam – you name it, CNC machines can handle it. Each material requires a unique set of parameters like cutting speed and feed rate, all of which can be controlled precisely by the CNC software.

It finds applications in an array of industries. In the aerospace sector, for instance, CNC machines are used to fabricate complex, lightweight components. In the automotive industry, they’re used to produce high-precision parts like gears and pistons. Even in the art world, these machines find use in creating intricate sculptures.

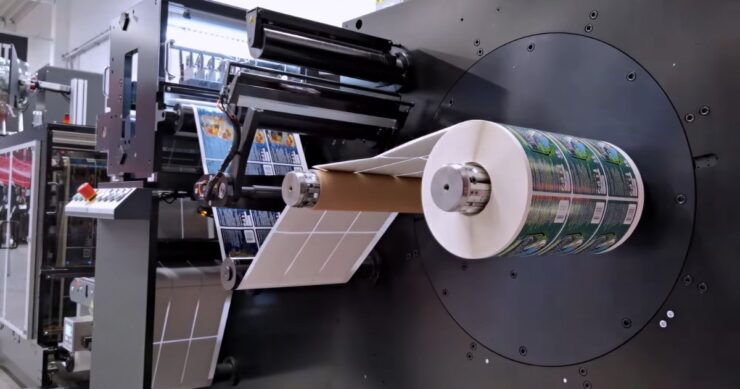

3. Efficiency and Productivity

CNC machining’s automated nature makes it a powerful asset for any manufacturing setup. It eliminates the need for manual labor, resulting in faster production times and increased productivity. A CNC machine can operate 24/7, only needing to pause for maintenance or repair.

What’s more, these machines can produce components in a single step that would require multiple operations in traditional machining. This means lesser setup time, reduced handling of parts, and thus, a streamlined and efficient production process.

4. Complex and Intricate Designs

One of the notable benefits of CNC machining is its ability to create complex, intricate designs with ease. Whether it’s a geometrical component for a car engine or a complicated surgical tool, CNC machines can handle it all.

Unlike manual machines that have limitations in terms of complexity and design, CNC machines can accurately produce intricate patterns, curves, and custom shapes. This opens up a realm of possibilities in terms of product design, facilitating innovation and creativity in manufacturing.

5. Consistency and Reproducibility

Consistency is key in manufacturing, and CNC machining excels at this. Since the entire process is automated and the machine operates based on precise software instructions, the produced parts are identical. This feature is vital when you need to produce high volumes of the same part without any variance.

Moreover, CNC machining ensures reproducibility. The digital template used to manufacture a part can be saved and used again in the future. This not only ensures that each part produced is identical to the last, but it also allows for seamless scaling of production as demand increases.

6. Time and Cost Savings

CNC machining offers considerable time and cost savings. The reduced setup and changeover times make the process faster, especially for complex and high-volume projects. Additionally, the machines can run unattended, freeing up workers for other tasks and reducing labor costs.

CNC machines also optimize material usage, minimizing waste and lowering overall production costs. The accuracy of CNC machining results in fewer mistakes and less material wastage. It’s an eco-friendly choice, aligning with the growing consciousness for sustainability in manufacturing.

7. Reduced Human Error

One of the significant advantages of CNC machining is the elimination of human error. In manual machining, errors can creep in due to fatigue or oversight, leading to product defects and waste. However, with CNC machining, the risk of such errors is drastically reduced.

CNC machines follow the programmed instructions to the letter, ensuring a high degree of precision and minimizing mistakes. This ability not only enhances product quality but also contributes to cost savings by reducing wastage and rework.

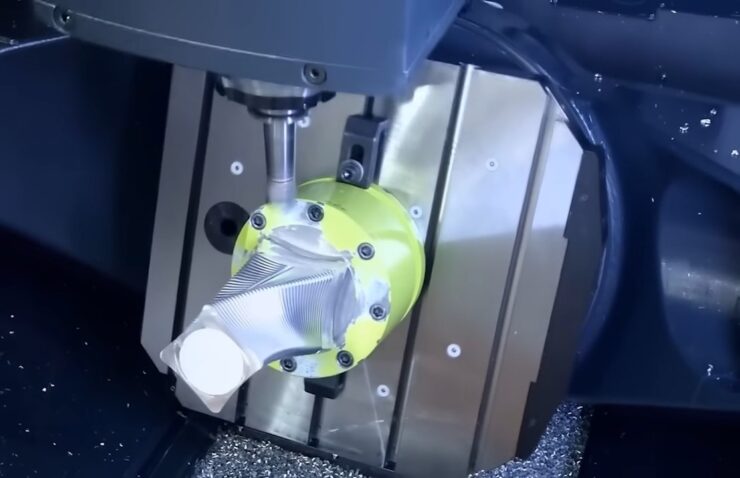

8. Complex and Multi-Axis Machining

The sophisticated design of CNC machines allows them to perform complex and multi-axis machining operations. They can rotate tools around multiple axes and even move tools and workpieces relative to each other, producing highly intricate parts.

Multi-axis machining can deliver highly accurate parts with smooth, flawless surfaces. This can be beneficial for industries where aesthetics and precision are crucial, such as automotive, aerospace, and jewelry manufacturing.

9. Customization and Flexibility

With CNC machining, customization and flexibility go hand in hand. Each product or part can be custom-machined according to specific customer requirements. Furthermore, the design can be easily modified in the software, allowing for quick adaptations to changing customer needs or design improvements.

This ability to switch between different designs without additional tooling or setup offers unparalleled flexibility, making CNC machining an ideal choice for industries where bespoke, made-to-order production is the norm.

10. Integration with CAD/CAM Software

The integration of CNC machines with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is a significant advantage. This allows manufacturers to design parts in CAD software, which can then be translated into programmable instructions by the CAM software.

This seamless integration simplifies the process of transitioning from design to production. It also allows for sophisticated simulations to be run before the actual production, identifying potential issues and optimizing the manufacturing process.

Conclusion

CNC machining offers a plethora of benefits that can revolutionize manufacturing processes. Its promise of precision, accuracy, versatility, efficiency, and ability to produce complex designs make it an invaluable asset in today’s fast-paced manufacturing world.

Whether you’re looking to increase productivity, reduce errors, or create intricate parts, CNC machining is a reliable and efficient solution. Embrace this technology and unlock your manufacturing potential.